Continued investment at Hambleton Steel with new modern methods of production

The UK steel industry is constantly progressing, from design capabilities to fabrication efficiencies. Fabrication has always been highly physical, with platers manually making each cut. Although the job remains demanding, modern machinery has greatly assisted the industry and our team at Hambleton Steel.

As part of our continued investment in newer technology, digital ways of working and the most up to date fabrication machinery, one of investments includes a Voortman V807 Coping machine which we installed in 2024.

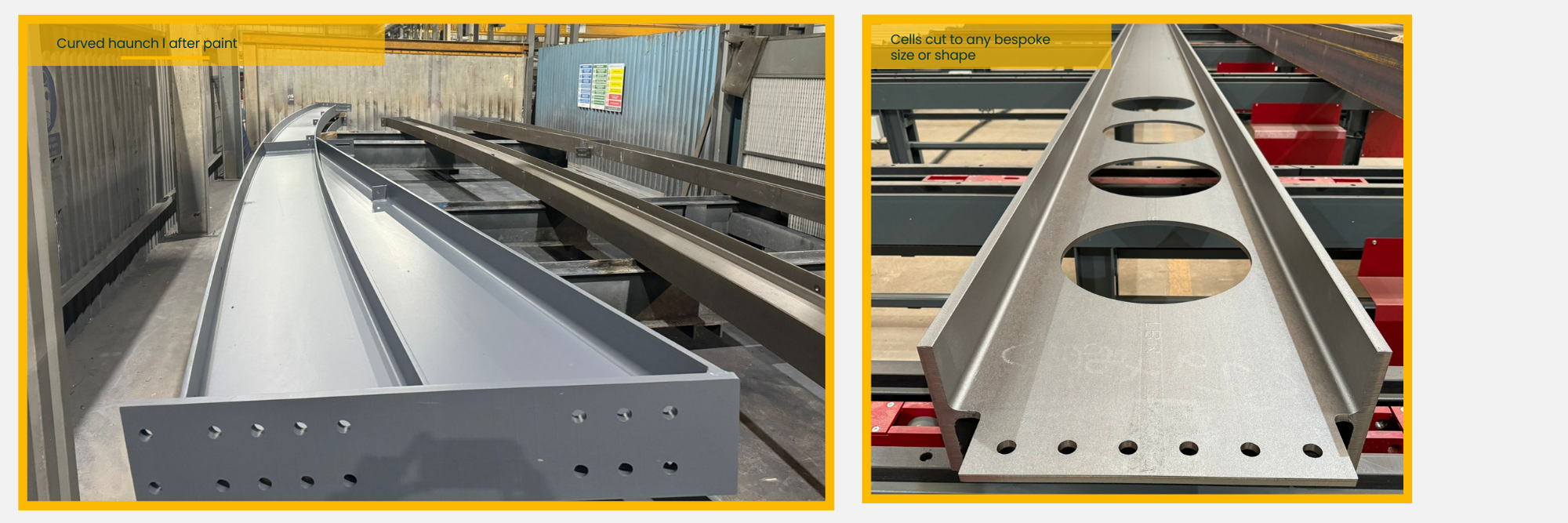

Cuts of high quality

Coping is an essential production process and manual coping can be time consuming, using the V807 coping machine has guaranteed a more efficient and high-quality cut. In addition time saving can be achieved when removing the manual processes such as cell cutting and layout marking.

A more dynamic approach

Our coping machine capabilities give our team greater flexibility compared to hand cutting methods. The V807 plasma cutter combines all these functions with an economic advantage over dedicated drilling, milling, sawing, punching, shearing and layout marking systems. Combining these processes in a “do-it-all machine” provides a quicker and fully automated system ensuring continuity and minimising operator dependence.

Exact measurements can be inputted without the need for manual adjustments, ensuring precise cuts at any angle while promoting worker safety on the job.

Hambleton Steel's Operations Director, Mike Dixon said "Our main objective was to ensure we increased fabrication capacity as well as improve quality and accuracy ensuring we meet our strategy to continually embrace modern ways of working in the business."